Engines

OE power, reliability, fuel and emissions performance with ready-to-fit remanufactured engines

Turnkey Solution

Fully assembled short, long and dressed remanufactured engines for quick and easy installation

OE TEsted

100% end-of-line dyno tested for OE performance, reliability, fuel efficiency and emissions

Sustainable

Save valuable material, resources and waste to landfill

Lower Cost

As well as being at least 25% cheaper, our reman engines will reduce ongoing operating costs

Made in State-of-the-Art Facilities

Our brand new, dedicated engine and electrical reman facility, located in Telford, boasts an in-house test cell complete with a SCHENCK W230 dynamometer and a suite of the latest ultrasonic cleaning equipment.

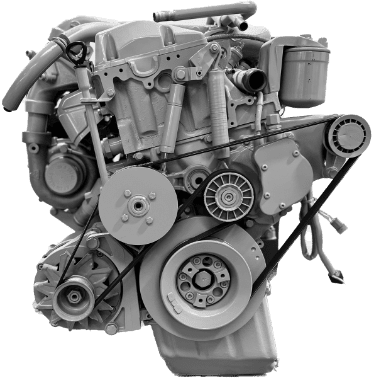

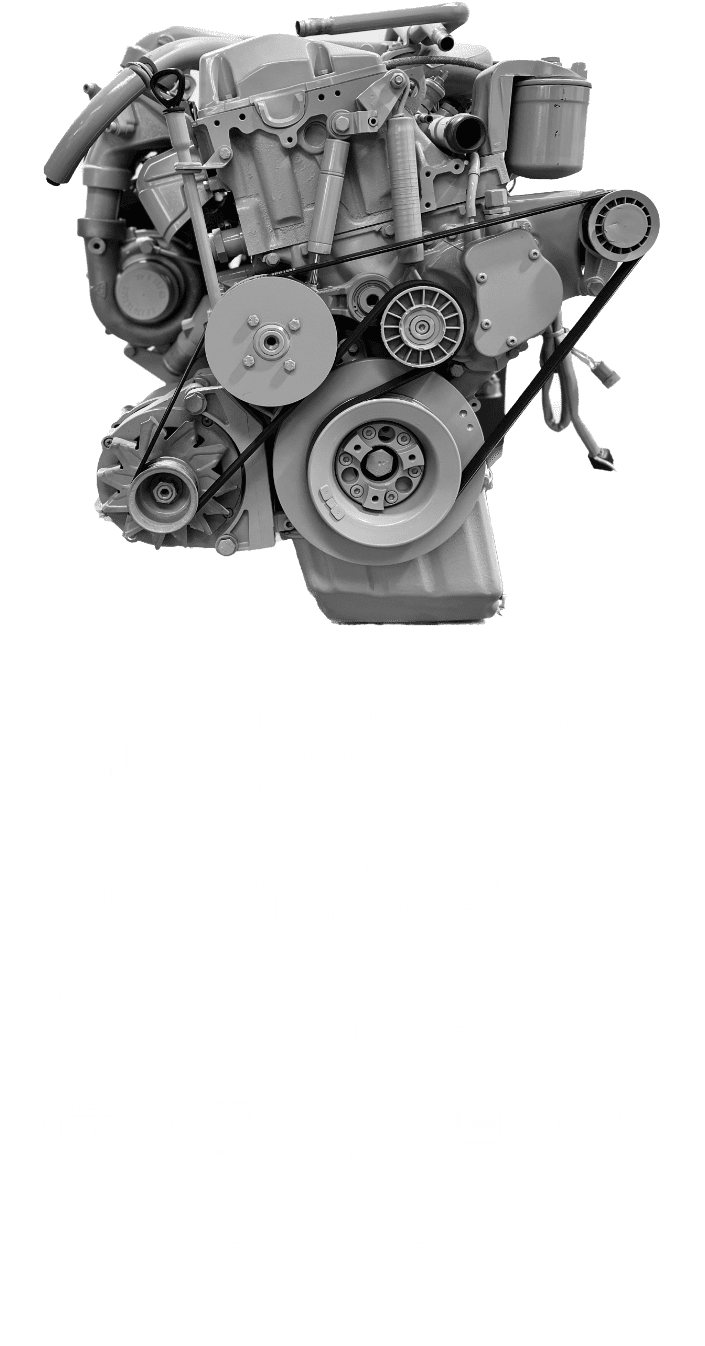

A Turnkey Solution

Leveraging our expertise as a global remanufacturer, we offer engines that can be dropped straight in. This includes everything – from the head, block, cam, crank, engine covers and sump, to auxiliary products such as the manifold, water pump, starter motor, alternator, turbocharger, fuel pump and injectors – many of which are remanufactured by us.

Made in State-of-the-Art Facilities

Our brand new, dedicated engine and electrical reman facility, located in Telford, boasts an in-house test cell complete with a SCHENCK W230 dynamometer and a suite of the latest ultrasonic cleaning equipment.

A Turnkey Solution

Leveraging our expertise as a global remanufacturer, we offer engines that can be dropped straight in. This includes everything – from the head, block, cam, crank, engine covers and sump, to auxiliary products such as the manifold, water pump, starter motor, alternator, turbocharger, fuel pump and injectors – many of which are remanufactured by us.

Quality Assurance

engine block, crank & cylinder head machined to OEM tolerances

100% wearable parts replaced with like-for-like OE

Quality Assurance

End-of-line dyno tested

Just to be sure, we run the engines up on their own power on our in-house dynamometer, to check for OE levels of power, torque, vibration, noise, emissions, oil and coolant temperature and turbo boost and manifold vacuum pressure.

No engine will leave our factory until it has met the OEM standard.

Finishing touches

Our engines are then sealed and painted for improved aesthetics and protection.

Preservation fluids are added, before being packed in frames, ready for despatch.

SAving Time and Money

Despite being just as good as new, our remanufactured engines are a fraction of the cost. Plus, they can help reduce total cost of ownership through shorter service times, improved fuel efficiency, better emissions performance and lower maintenance costs.

Saving the Planet Too

By giving used parts a new lease of life, Carwood remanufactured engines use up to 70% less material and 85% less energy, create less waste at every stage and produce fewer emissions than new.

What Else We Offer

In-Field Technical Support

In-Field Technical Support

Remanufactured to British standard BSI AU 257:2002

Remanufactured to British standard BSI AU 257:2002

ISO 9001:2015 and ISO 14001:2015 certified

ISO 9001:2015 and ISO 14001:2015 certified

Factory Standard Warranty

Factory Standard Warranty

More Reading

Sustainability

Learn how we make “Quality parts that don’t cost the Earth”. Learn More

Innovation

Learn how Carwood is embedding innovative thinking in everything we do Learn More

Circular Economy

Read how Carwood is closing the loop on material flow Learn More

ADVANCED SUPPLY CHAIN

Learn how we get the right parts, to the right place, at the right time. Learn More