Back in its day, the concept of remanufacturing – returning a used product to a like new condition – was born more out of necessity. Due to the scarcity of natural resources, and those that existed being diverted into the war effort to build planes etc, car and truck parts had to be reused. Yet, whilst it was very much about fulfilling a need, it was still a new idea for its time, and in that sense innovative.

Fast forward to now, and it still is. Just much more so. Although the fundamentals of reusing parts may not have changed, the level at which this is done, has. As a pioneer in this field, Carwood, has been instrumental in driving forward these changes; embracing the concept of reusing parts, but re-imagining just how to do it.

The result, a highly-advanced, highly-engineered process, that is much more akin to the production and quality of the original part, but importantly, still allows both the material and value added to be harnessed, making it much more cost and environmentally friendly too. An innovation in itself.

The challenge now is being able to continue to push these boundaries. Given the ever-growing sophistication in today’s vehicles and equipment – more electronic components, higher pressures, higher tolerances, lower weight, less space – remanufacturers like Carwood are having to find increasingly novel ways of maintaining or bettering these same OE standards, without adding cost or critically, material and resources back in. That means using new technologies, new ideas and new ways of thinking.

Improving on the original

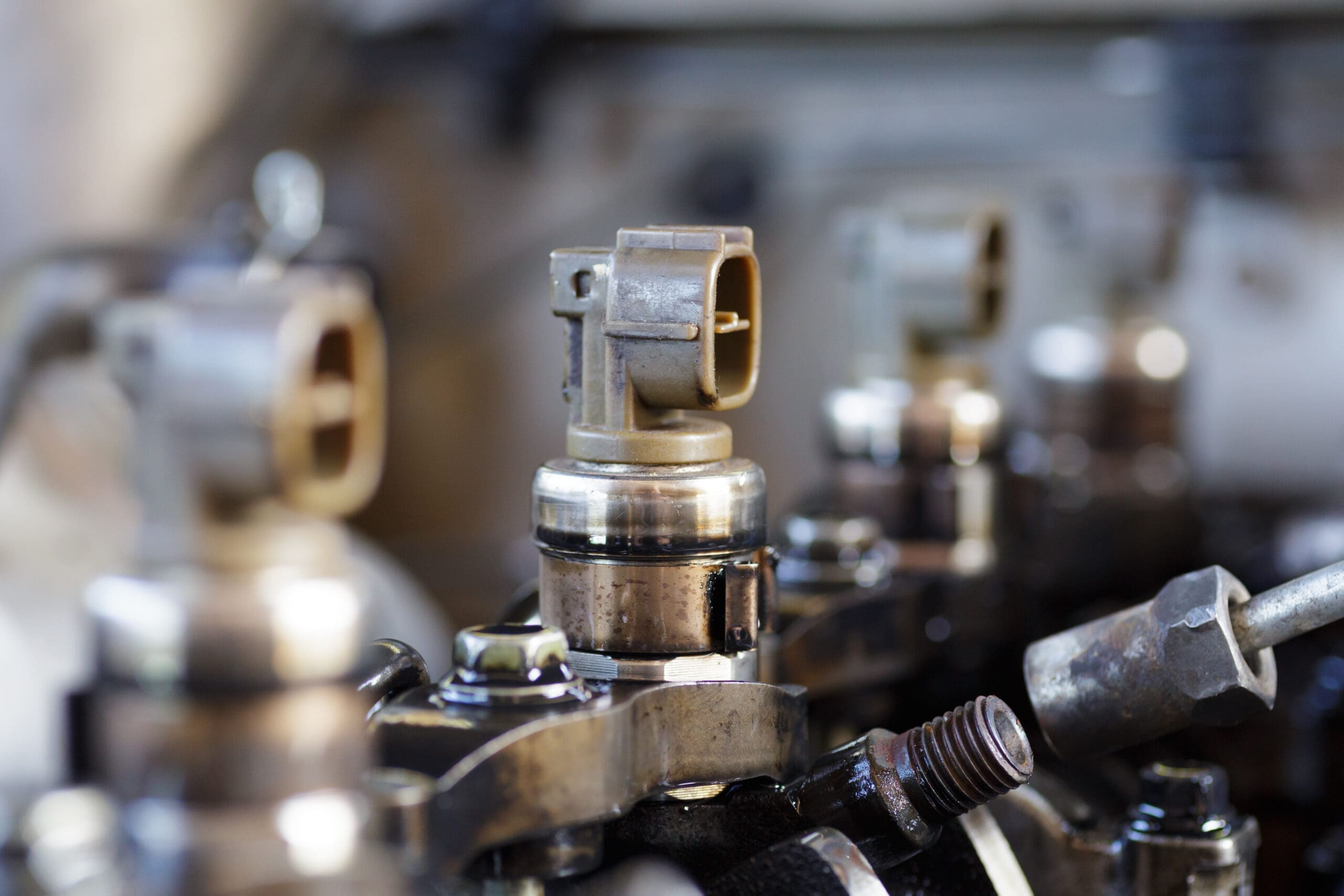

For example, when introducing a new range remanufactured injectors for a leading engine manufacturer, we re-engineered the injector’s control valve to address known design flaws. By optimising the valve’s seat angle, flow control orifice, valve lift and plunger to bore clearance, we were able to reduce backleakage resulting in fewer pumping losses, and improving both engine efficiency and injector performance, reliability and durability, whilst meeting tier 3 emissions standards.

Sticking with injectors, Carwood engineers designed their own glitch methodology, with dedicated electrical drive hardware, to dynamically set and configure the control valve once installed inside the injector. By electrically determining when the valve hits maximum lift, we can accurately set the control valve airgap to enable consistent opening and closing injection events. This innovative solution ensures the injection rate profile matches the OE performance, whilst generating a 95% first-time-pass-rate during end-of-line testing. No one else has this capability in the aftermarket.

Innovating for the future

We’re bringing just as pioneering approaches to alternative fuels. With integrated gearboxes, sophisticated electronic control and hi-tech cooling systems, it’s not surprising that aftermarket companies are shying away from work on electric motors in hybrid and electric vehicles. Not us. Whilst it’s not yet commercially available, and whilst we can’t say too much for the risk of giving away our IP, our reman programme for electric drive motors, will deliver a much more cost-effective, convenient and environmentally friendly service option.

Pioneers in motorsport

Of course motorsport is known for ground-breaking advances. And our approach is no different. Using technology and engineering from a LeMans winning car, we’ve developed a carbon fibre reinforced composite cover and aluminium/silicon particle reinforced metal matric composite casing in house. Combined with titanium and ceramic components, previously made from stainless steel, we’ve reduced the overall weight of a race alternator by over 50%. When every pound can make a difference, this is game-changing

…Innovating for the past too

Ingenuity, however, is not just limited to new technology. Our engineers need to be equally creative when it comes to older products. Here, the drawings, parts, tools etc may no longer exist, so we have to completely reverse engineer it, dissembling the product piece-by-piece or layer-by-layer to work out how to recreate it. For example, we recently remanufactured a PPE fuel lift pump, date stamped 1965. Because only the original pump liner and end cap were available, Carwood engineers had to rewind both the armature and field coils, weld and machine the main castings, and modify the seal arrangement. It was a similar story for an alternator for a Wolf Land Rover introduced in 1994. Although not quite as old, the same challenges existed – this time, however, no original parts were available. Fortunately our global purchasing team were able to source like-for-like OE parts, which we certified, just to make sure. We then set about designing and manufacturing our own OE spec EFI cowls, and completely rewinding both the rotor and stator. Both were restored to their original spec, if not better. For parts up to 60 years old, this is no mean feat.

Bespoke solutions

Nor is it for modern day, niche jobs.Faced with the prospect of a 9-month wait for a new wiring harness, a leading construction equipment manufacturer asked Carwood for help with a one-off project. We were only too happy to assist. By quickly getting to grips with the complex electrical requirements, space constraints and other environmental factors, we were able to redesign and manufacture a whole new, custom-built wiring loop to the original spec. Slashing both leadtimes and costs. Cue another happy customer.

Making installation even easier

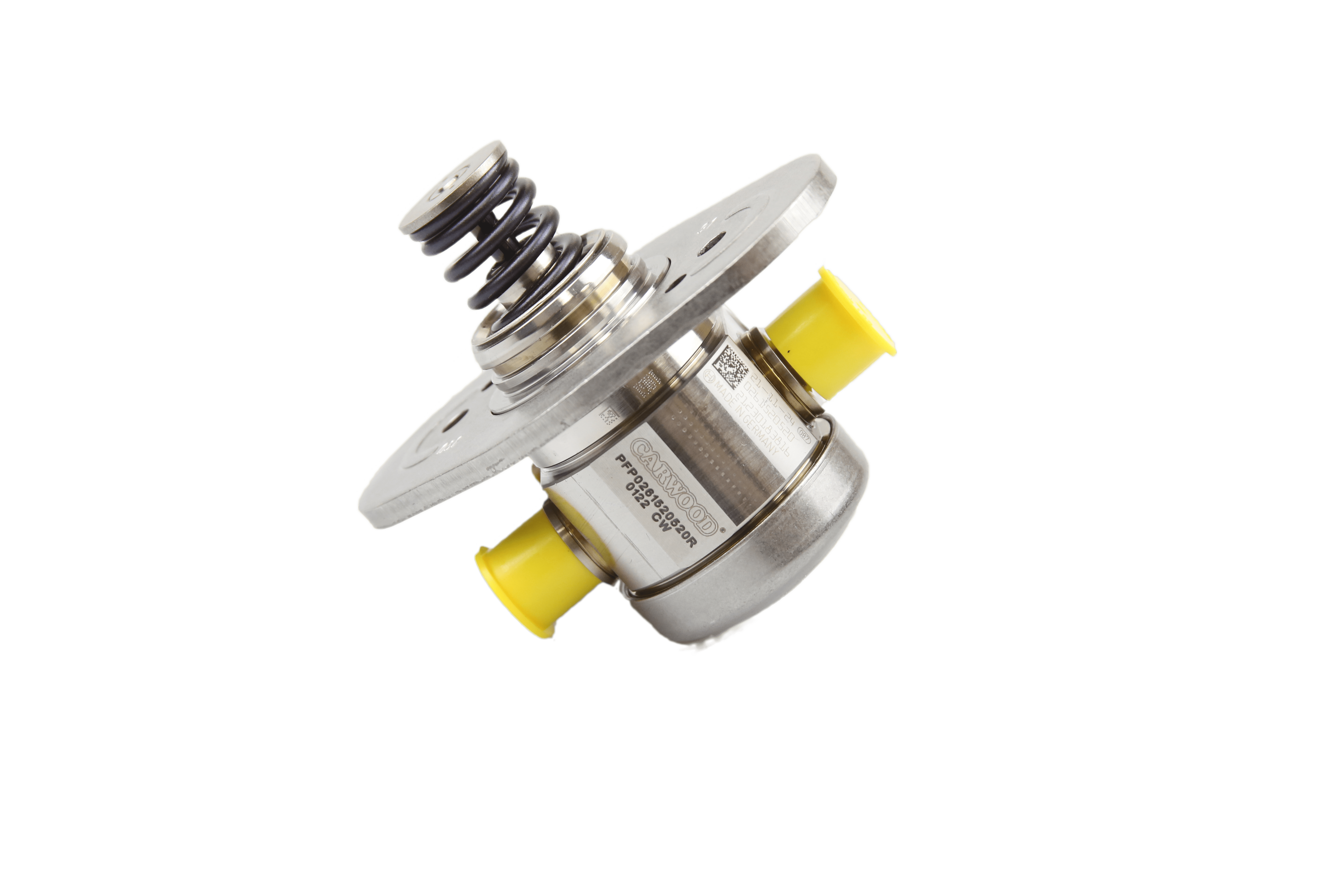

We’re always looking for innovative ways to make fitting our products even easier too. Our B58TU uprated high-pressure fuel pump for BMW performance applications is the perfect example. In addition to strengthened components, enabling a continuous 350bar max rail pressure throughout the engine speed range, and an increased plunger allowing 10 percent more fuel volume per pumping event, no additional modifications to the engine wiring loom and hydraulic connections are required. So the customer gets better performance, straight from the box. And whilst other solutions may now be on the market, we were the first to do it.

Just a few of many examples. Bottom line, innovation is about creating new ideas and new approaches, and never resting on our laurels. Something that is very much part of our DNA. And as you can see something that we put into practice every day.