According to leading industry associations, including The European Association of Automotive Suppliers (CLEPA), Motor & Equipment Remanufacturers Association (MERA), and Automotive Parts Remanufacturers Association (APRA), remanufacturing is defined as… “a standardized industrial process by which cores are returned to same as new, or better, condition and performance. The process is in line with specific technical specifications, including engineering, quality and testing standards. The process yields fully warranted products. With this in mind, every one of our parts – be it a fuel injector, starter motor, engine or turbocharger – and regardless of who it’s for – a vehicle manufacturer, fleet, or independent garage – goes through the exact same process. This involves…

![]()

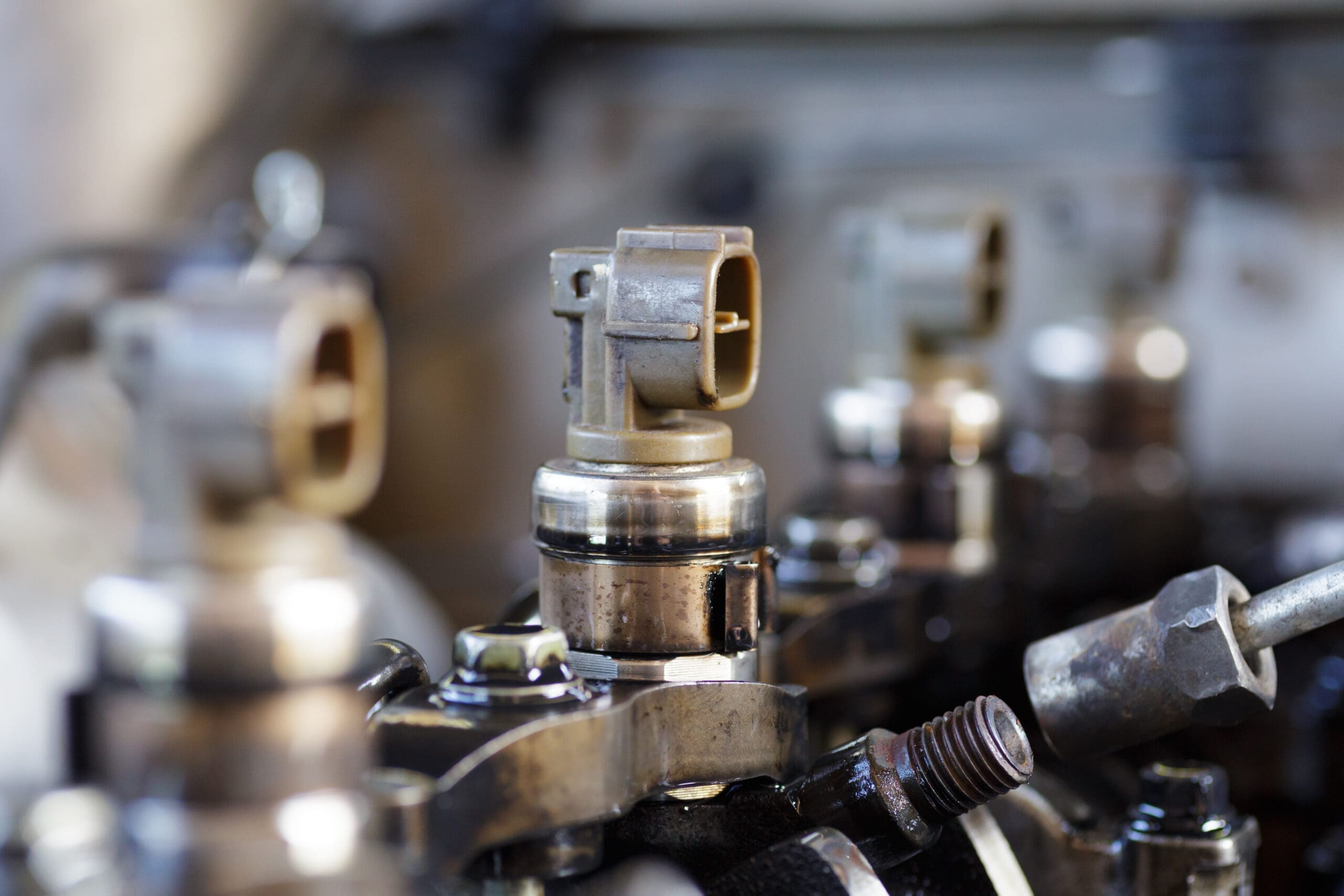

Core inspection: Every unit is inspected against our acceptance criteria to assess its suitability for remanufacture. Only good core is used, because what we put in at the start, has a bearing on what comes out at the end.

![]()

Disassembly: The units are then stripped down – any products with cracks, scrapes, faulty connectors, missing components, heavy corrosion etc are rejected and the material recycled. No gaskets or seals are reused.

![]()

Cleaning: All reusable parts are put through a rigorous multi-stage cleaning process to remove any unwanted particles and contaminants – this includes ultrasonic cleaning, low VOC or water (low energy process) and surface conditioning with pressurised application specific media.

![]()

Reinspection: We then inspect again – this includes the measurement and testing of individual components to ensure they are within OE tolerances.

![]()

Part replacement: All out-of-tolerance and single-use parts, such as o-rings, seals and gaskets, are replaced with like-for-like OE parts, that meet or exceed OE specifications.

![]()

Assembly: We then reassemble the units following OE-approved build specifications and processes – our fuel pumps and injectors, for example, are assembled in an ISO certified, Class-7 clean room, capable of filtering down to 0.5 microns.

![]()

Test and calibration: All units are end-of-line tested using the very latest test equipment and test plans – no product will leave our factory until it has met OE performance standards, as a minimum. In the case of common rail injectors, a new calibration code or trim code is generated to improve the precision and timing of the injected fuel for optimum engine, fuel consumption and emissions performance – this code should be programmed into the ECU when the injector installed in the vehicle.

Only through this highly-engineered, rigorous process, can we be confident that every Carwood reman part has been returned to the vehicle manufacturer’s original factory specification. Ensuring a product that’s just as good as new, sometimes better, with a warranty to match. Whilst also being better for the environment, and our customer’s wallet.