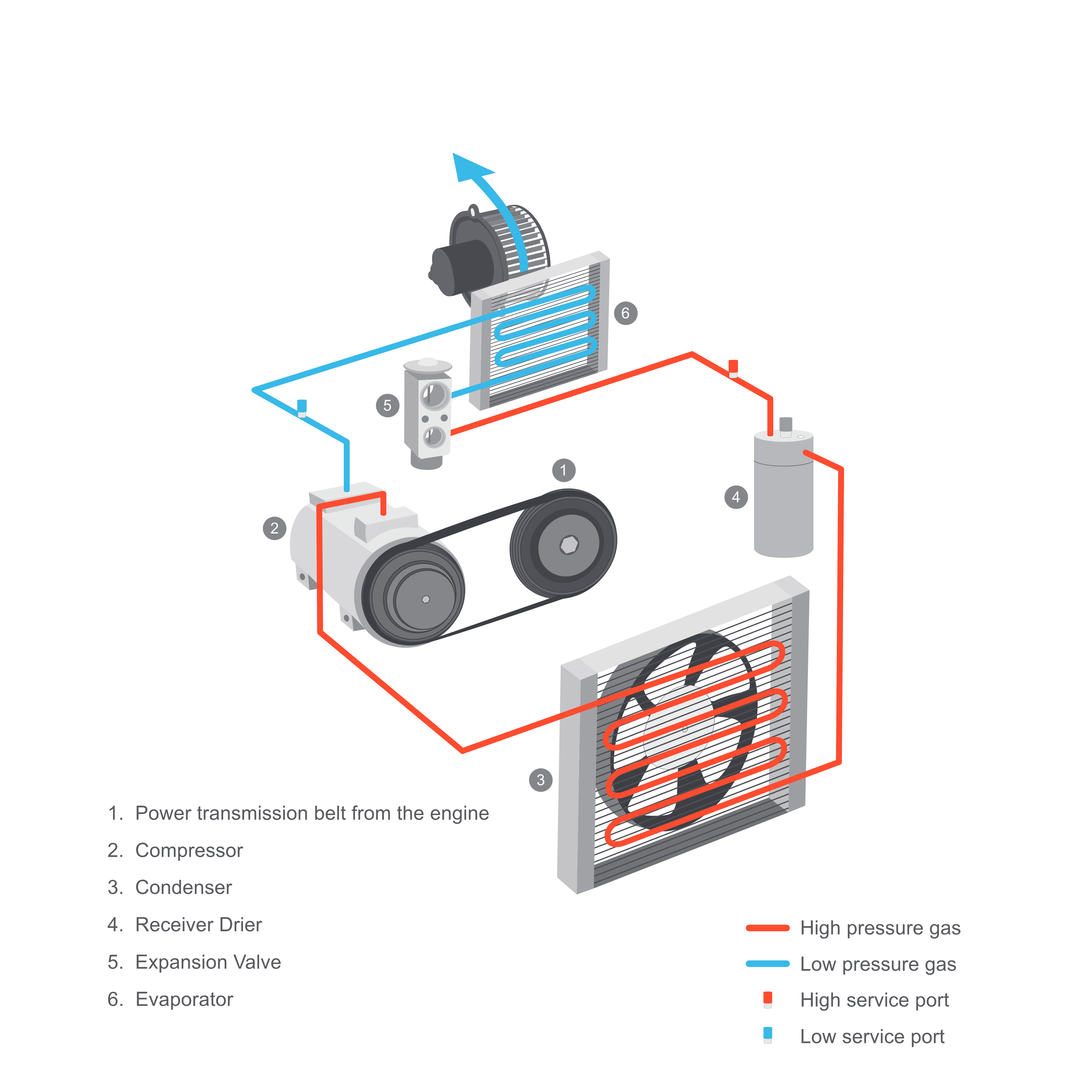

By understanding how each of these parts work, and how and why they fail, you’ll be able to pinpoint when something isn’t working as it should, and then fix it. Our quick guide below will help you do this:

Compressor:

The main component in a vehicle’s air conditioning system, the compressor is usually a mechanical pump, driven by a belt connected to the crankshaft. Like its name suggests, its job is to compress the refrigerant, and deliver it at high pressure and high temperature to the condenser, paving the way for the cooling process.

If this is not possible though, because of frequent shorter journeys for example, the vehicle’s ECU will take measures to prevent the filter from clogging. Known as active regeneration, it injects a small amount of fuel upstream of the DPF, post combustion, to increase the exhaust temperature and trigger regeneration itself.

Causes of failure:

- Lack of lubrication due to refrigerant leak

- Incorrect quality and quantity of compressor oil

- Excessive air and moisture in system

- Seized clutch

Symptoms of failure:

- Reduced cooling

- Complete system failure

- Noises when the A/C is switched on

- Clutch not functioning

- Burning rubber smell when A/C is on

- Excessive wear or damage to the compressor or compressor belt

Troubleshooting tips:

- Switch the A/C system on and off and listen for changes in noises

- Inspect system for contamination and flush if needed

- Oil balance the compressor

- Use the right compressor oil

- Rotate the compressor clutch prior to compressor installation

- Evacuate the system

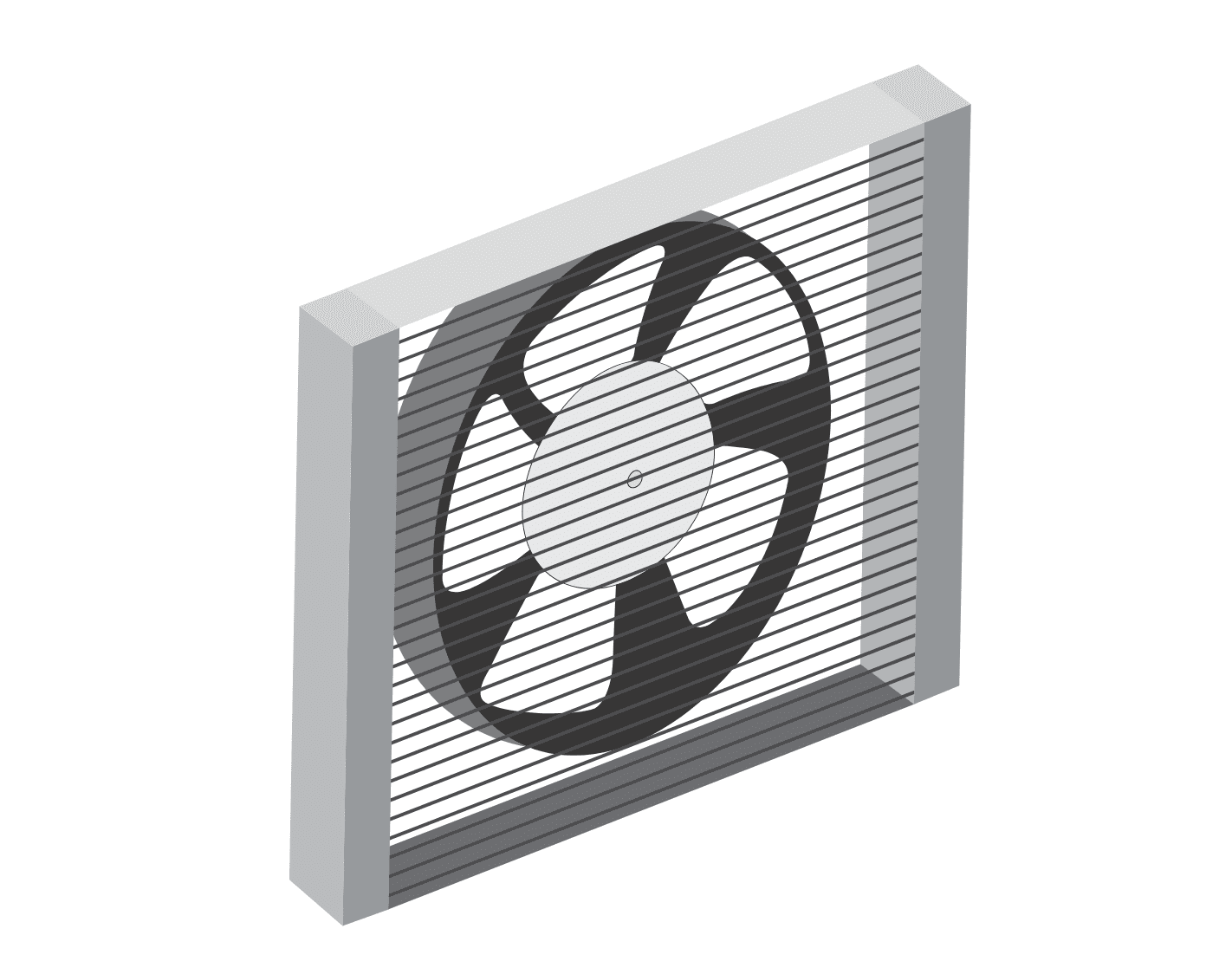

Condenser:

Positioned between the grill and the radiator, the condenser releases the heat absorbed by the refrigerant while it’s flowing through the evaporator. Here, it ‘condenses’ the refrigerant, transforming it from a high-pressure gas, into a high-pressure liquid.

Causes of failure:

- Blockage of the pipes and fins due to dirt, dust, leaves etc

- Contamination from metal particles due to compressor failure

- Refrigerant leaks

- Damage from front-end collisions or stones

Symptoms of failure:

- Blowing warm air from vents

- Reduced cooling

- A/C system failure

- Fluid pooling under the vehicle

- Continuously running condenser fan

- Damage or dents to the condenser

Troubleshooting tips:

- Check condenser for contamination

- Flush debris from inside condenser

- Check for leaks

- Pressure test on the high-pressure and low-pressure sides

Receiver drier:

Located in the high-pressure side in systems with an expansion valve, the receiver dryer or dehydrator, temporarily stores refrigerant during periods of low cooling demand, whilst also filtering debris and moisture from the system.

Causes of failure:

- Excessive moisture in the system

- Saturated desiccant

- Restrictions due to debris

Leaks at the connections

Symptoms of failure:

- Reduced cooling

- Mouldy smell which worsens when A/C system is on

- Rattling sound caused by damage or contamination to chambers

- Refrigerant leakage

Troubleshooting tips:

- Check maintenance intervals (every 2 years)

- Replace every time the system is opened

- Leak test/correct fit of the connections/damage

- Pressure test of the high-pressure and low-pressure sides

Expansion valve:

Positioned between the high- and low-pressure sides of the system, the expansion valve controls the flow of refrigerant throughout the A/C system, based on the temperature of the evaporator and the demand on the system. Too much and the core of the evaporator will get too cold and eventually freeze over. Not enough, and it could get too hot and overheat. The expansion valve takes a high-pressure liquid and as it passes through its narrow interior, transforms it into a low-pressure (aerosol) liquid, ready for the change of state to gas in the evaporator.

Not all systems have an expansion valve, some have a fixed orifice tube, which performs a similar function – providing a pressure differential with a high-pressure liquid on one side, and a low-pressure liquid ready to evaporate on the other.

Causes of failure:

- Mechanical failure of the rod that opens and shut the valve

- Failure of the sensing bulb

- Blockage of the narrow interiors due to dirt, residue etc

Symptoms of failure:

- Reduced cooling

- Fluctuating cabin temperatures

- Inconsistent air flow

- Hissing sound

- Frost on the vents or the valve itself

- Compressor constantly running

Troubleshooting tips:

- Visual inspection

- Acoustic test

- Check connection pipes for tight and correct fit

- Check components and connections for leak-tightness

- Temperature measurement on the line system

- Pressure measurement with the compressor switched on and the engine running

Evaporator:

Positioned behind the dashboard, the evaporator, also known as the evaporator core, is responsible for cooling and dehumidifying the air. As cold, low-pressure liquid refrigerant flows through the evaporator, the blower fan moves warm air from the vehicle’s interior across it. Since heat always migrates to cooler areas, the cool refrigerant absorbs the heat. The moisture in the air also condenses on the evaporator’s cool surface, before dripping out of a drain tube.

Causes of failure:

- Blocked pipes due to dirt, leaves, mould etc

- Refrigerant leaks from a faulty seem or weld

- Corrosion due to prolonged exposure to salt, moisture etc

Symptoms of failure:

- Reduced cooling

- Bad odours

- Poor ventilation performance

- Visible leak under vehicle

Troubleshooting tips:

- Check evaporator for contamination

- Inspect for damage

- Check connection pipes for correct fit

- Leak test

- Pressure measurement with the compressor switched on and the engine running

- Temperature measurement on the input and output line