The diesel injector – a key driver in emissions reduction

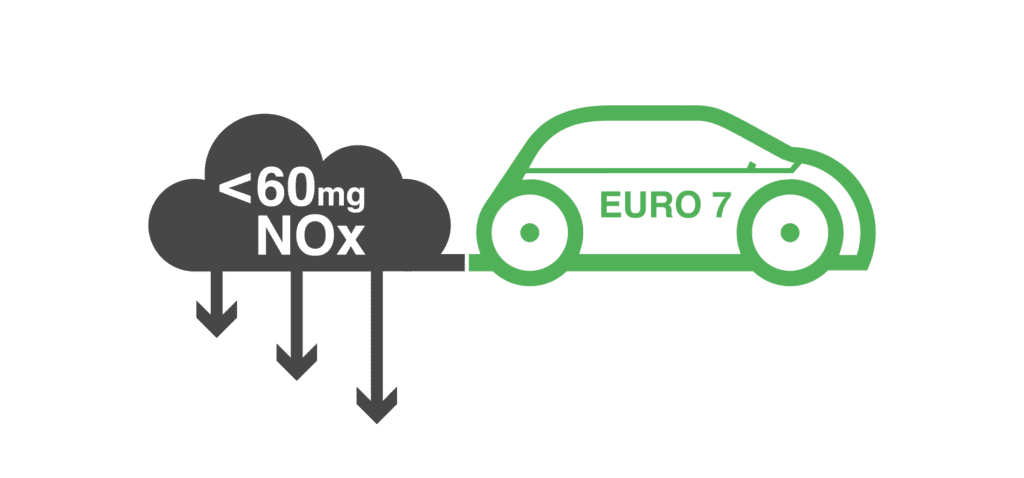

Humble, it’s anything but. With the advent of electronic control in electronic unit and common rail systems, today’s modern diesel injector can inject even more precise quantities of fuel, at even higher pressures – 2,000 bar plus compared with 1,200 in a mechanical diesel injector – multiple times per combustion cycle. This makes for an optimal fuel and air mixture in the combustion chamber, and therefore a much cleaner, more efficient burn.

How modern fuel injection technology reduces emissions

Through these advances – higher pressures, multiple injections, precision delivery – diesel fuel injectors can significantly reduce Nitrogen Oxides (NOx), Particulate Matter (PM) and other harmful pollutants, as follows:

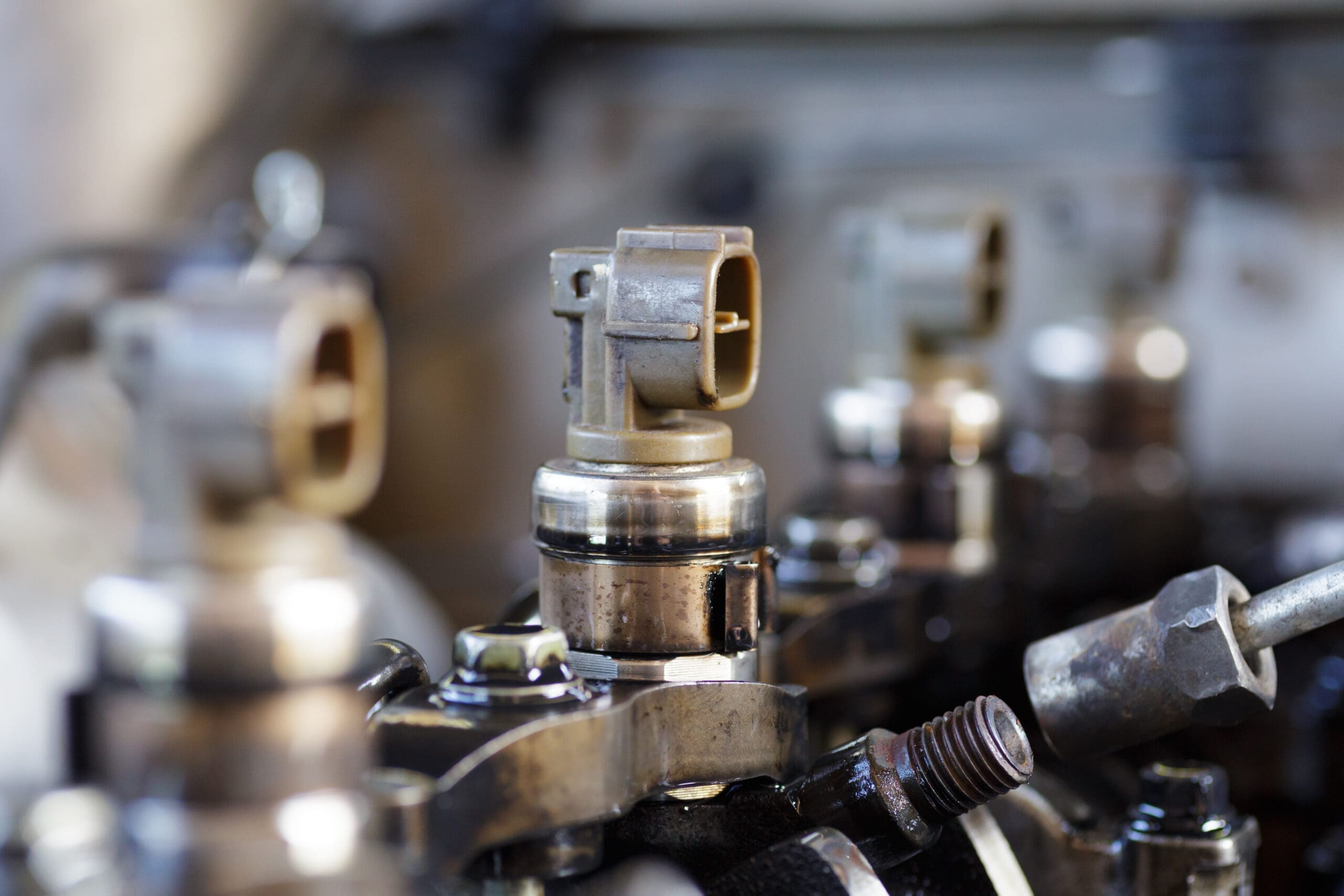

- Higher pressures: the higher injection pressures in modern diesel injectors enables finer fuel atomisation, better air-fuel mixing and improved control of injection timing. This results in a more complete and controlled combustion, reducing both NOx emissions, typically produced at higher temperatures, and other harmful by-products like PM and Hydrocarbons.

- Multiple injections events: today’s common rail injectors can perform multiple injection events during a single combustion cycle. By injecting fuel at different points, for example pilot and post injection, it allows for a more stable combustion. This helps lower emissions and improve fuel efficiency.

- Precise timing: with electronic control allowing for much better control of both injection timing, and the quantity of fuel injected, modern diesel engines can maintain lower operating temperatures. This limits the formation of NOx and soot or PM.

- Optimal fuel delivery: modern diesel injectors can also adjust delivery of the fuel in response to engine load, engine speed and other ambient conditions. By delivering the right amount of fuel, at the right time, as demanded by the engine, it uses less fuel, which means less is burned, further reducing emissions. Learn more about how modern diesel injectors improve engine efficiency.

What’s next! The future of fuel injection technology and Euro emission standards

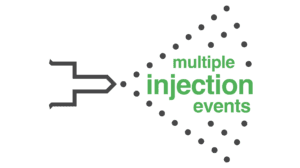

Increasingly stringent emissions standards have paved the way for many of these advances… and will continue to do so. Coming into effect in 2025, Euro 7 will be the strictest standard so far, requiring all new cars sold to emit less than 60 milligrams of NOx, whilst also limiting non-exhaust emissions from vehicle brakes and tyres etc.

To achieve the latest Euro emissions standards, OEMs such as Bosch, Delphi, Denso and Continental, will need to consistently deliver injection pressures upwards of 2,500 bar, add more sophisticated electronic control systems, and optimise the injector’s design to feature multi-hole nozzles and higher specification coatings and material that can withstand the higher pressures and temperatures involved.

With an increasing focus on real-time performance monitoring under Euro 7, next generation diesel injectors will also need to be able to adapt to live feedback from aftertreatment systems such as Diesel Particulate Filters (DPF) and Selective Catalytic Reduction (SCR), so that they can continually achieve a cleaner combustion, and lower emissions, no matter what the conditions.

Carwood’s contribution to cleaner diesel technology

As an OE-approved remanufacturer our mission is simple: to deliver equal levels of OE fuel, engine and emissions performance throughout the vehicle’s lifetime, but in a more sustainable, affordable way.

To achieve this, Carwood’s remanufactured injectors are put through a highly engineered process that is more akin to the production of the original part. This involves the same stringent inspection, cleaning, rebuild, test and calibration procedures as the OE – the latter a critical step in ensuring that that timing and quantity of fuel are realigned for optimum combustion.

We can also incorporate technology updates or new features that have been added to subsequent new parts, into the old part, so there are times when our injector is cleaner and more efficient than the original.

Environmental benefits of remanufactured injectors

The real benefit of OE-approved remanufacturing lies in its ability to retain the materials and value added – labour, energy, and manufacturing processes – that were embodied in the original part during production. By returning a used part to its original condition, instead of producing a brand new one, remanufacturing provides a proven quality, low-cost alternative to new, that’s better for the environment. It can save up to 70% of the resources versus new, use around 85% less energy, reduce CO2 emissions and help keep material in use for longer, meaning less material ends up in landfill. Learn more about how Carwood is helping to close the loop on material flow.

So as the diesel industry continues to develop cleaner, more efficient fuel injection systems, so too will Carwood. With an industry leading line-up of OE-approved remanufactured injectors, aftermarket companies can access the same OE performance, for both current and next-generation vehicles, at a fraction of the price and environmental footprint.