An introduction to diesel injectors

Unlike their gasoline equivalent, diesel engines rely on compression to ignite the fuel. In other words, the heat generated by compressing the air within the combustion chamber, ignites the fuel, rather than the spark plug in a petrol engine. How they do that differs slightly depending on the type of injector, but the principle is the same; when fuel is needed, the injector opens and delivers highly pressurised fuel through the nozzle, turning it into a mist. A precise quantity of atomised fuel is then sprayed into the combustion chamber, at the exact right time, where it mixes with air and ignites to create the energy needed to move the piston. In a modern diesel engine, this can happen multiple times in a single stroke.

How has the diesel injector evolved – the different types

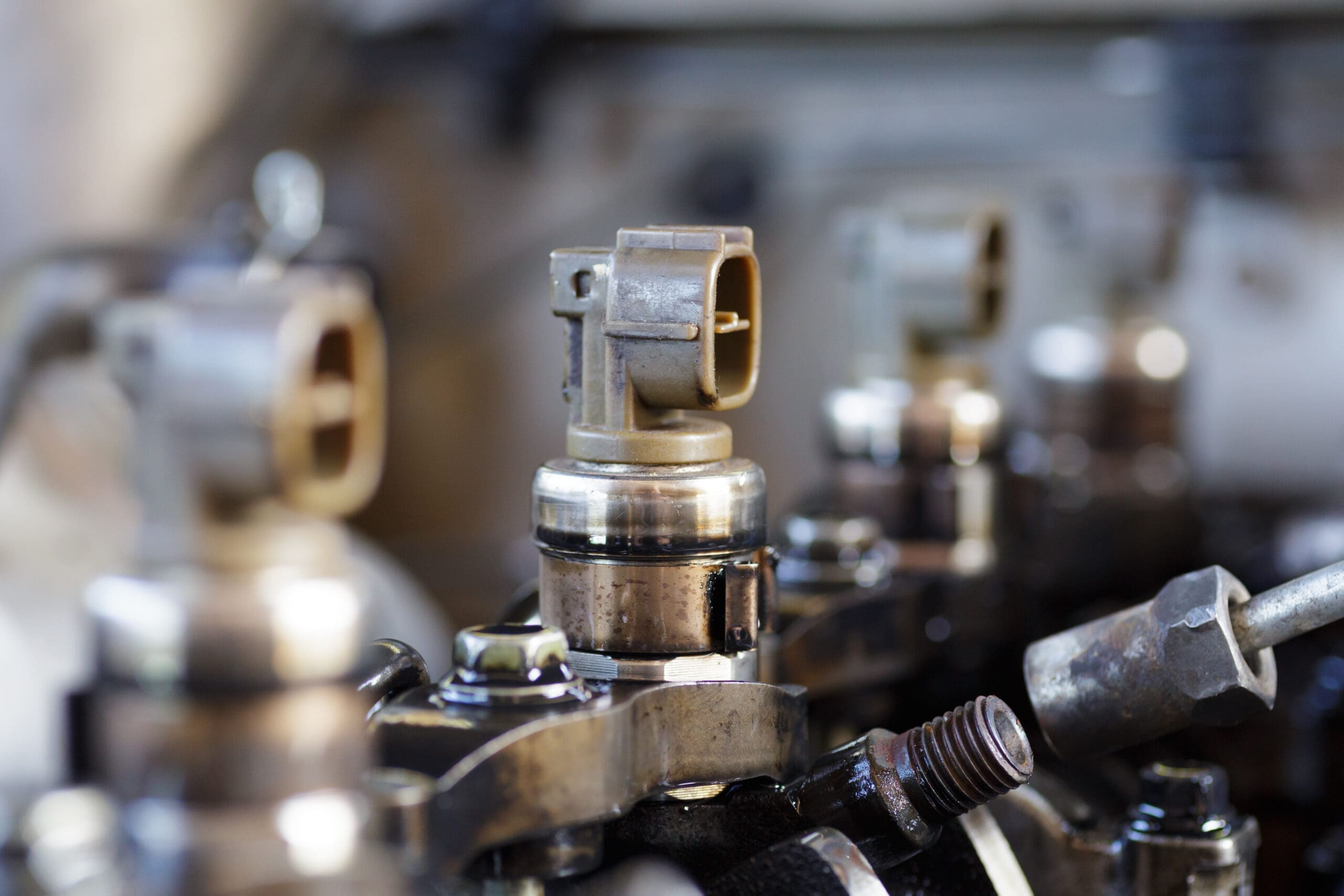

Driven by a demand for improved performance, fuel economy and emissions control, the diesel injector has changed beyond recognition. 20 plus years ago, diesel injectors were simple mechanical devices. Still found in older applications today, mechanical diesel injectors use a camshaft to regulate the quantity and timing of injected fuel.

Nowadays, most injectors are electronic controlled, as part of a common rail system, hence, their other name – the common rail injector. In an electronic injector, the engine’s electronic control unit (ECU) is able to adjust the timing, quantity and injection pressure, based on real time engine conditions, resulting in superior power output, emissions performance and fuel efficiency.

Although common rail is now the standard for passenger cars and commercial vehicles, in some heavy-duty engines, the injector and pump is combined into a single unit. Also known as a unit injector, and still electronically controlled, it saves space, whilst allowing more accurate and flexible fuel delivery.

For high-performance diesel engines, where response times are critical, piezoelectric injectors are another option. They feature piezoelectric crystals, which expand when an electric voltage is applied, to open and close the nozzle at ultra-fast speeds.

How do modern diesel injectors improve engine efficiency?

By regulating how much fuel is injected into the combustion chamber, and when, today’s electronically controlled diesel injectors help achieve the optimal air-fuel ratio needed for a cleaner, more complete burn. This helps improve the engine’s efficiency in several ways:

- Reduced emissions: a cleaner, more complete combustion process reduces the amount of unburned fuel, and the formation of harmful pollutants like particulate matter (PM) and nitrogen oxides (NOx), helping meet ever stricter emission legislation, and improving the engine’s efficiency further still.

- Better fuel economy: by delivering an optimal mix of fuel and air into the engine’s combustion chamber, the injector helps to maximise the combustion process, and improve fuel and engine efficiency.

- Improved engine performance: by regulating the quantity and timing of fuel with millimetre precision, modern diesel injectors help to ensure better acceleration, idling and faster throttle response, resulting in a more responsive, smoother running engine.

- Extended engine life: because the engine is running smoother, there will be less strain on the engine and its key components, enhancing its lifespan.

The importance of quality diesel injectors

Using high-quality diesel injectors from an OE-approved supplier like Carwood, is therefore crucial. A quality diesel injector, built to the same standard as the original unit that was fitted on the vehicle assembly line, will ensure the right amount of fuel is injected, at the right time, for optimal engine performance. In other words, it’s doing the job it was designed to do.

Anything below this standard, may result in poor fuel atomisation, incorrect timing or the wrong quantity of fuel being injected, and ultimately incomplete combustion. This can cause an increase in the production of smoke and other harmful pollutants, reduced engine performance, and higher fuel consumption, as the engine will inevitably have to work harder to compensate. Similarly, since a substandard injector may inject fuel at the wrong time or in an uneven pattern, it can cause engine knock or pinging, when then the air-fuel mixture in the cylinder ignites prematurely, and/or engine misfires. Both will impact the engine’s power output and driveability.

Over time, inferior quality diesel injectors will also place additional strain on the engine and other key parts. This can cause premature wear and tear to components, and if left unchecked, potentially irreparable and costly damage to the engine. So whilst an OE-quality injector, may cost a little more at the outset – note Carwood’s remanufactured injectors are a cost-effective alternative to new – they are sure to save money, and hassle, in the long run; improving engine longevity, vehicle reliability, and reducing fuel bills ongoing.

Maintenance and care of diesel injectors

As well as choosing a quality diesel injector, it makes sense to look after them. Like most components, they are prone to wear and tear, with common issues including particle contamination, corrosion, heat soak, leaks and even missing or incorrectly seated sealing rings due to poor installation. All of which can affect the injector’s ability to perform, and in turn the vehicle’s drivability, emissions and/or fuel economy. Any fuel left in the injector after engine shut down, for example, will be ‘baked’ onto it by the residual heat, creating deposits that clog the injector, and obstruct fuel flow.

A clean, well-maintained, OE-quality diesel injector will not only reduce the likelihood of such issues, but can contribute to improvements in a vehicle’s lifespan, engine, emissions and fuel performance too. So it’s important to follow some simple maintenance steps:

- Use quality diesel fuel: fill up at a reputable station to prevent the risk of injector-clogging contaminants entering the fuel. It’s also a good idea to run a tankful of a premium diesel through the engine every 1,000 miles or so. Whilst more expensive, it will help to shift soot and other deposits, enabling the vehicle to run smoother, and saving money in the long run.

- Use a fuel additive: for the same reason, you might want to add a diesel additive to your tank. As well as enhancing lubrication, and reducing friction and wear in the system, it will help prevent the build-up of deposits.

- Change the fuel filter: replace the fuel filter, as per the vehicle manufacturers recommended service intervals, and always fit an OE-quality unit. This will prevent dirt and debris from reaching the injector – with today’s super fine tolerances, even the tiniest amount can cause significant wear.

- Avoid frequent short trips: driving slowly for short periods, may prevent the engine from reaching the required temperature for optimal combustion, which will impact the vehicle’s emissions and fuel efficiency. It can also block the diesel particulate filter, or DPF, and so the injectors won’t be able to accurately regulate the fuel pressure.

- Check your engine: keep an eye on the engine’s performance—if you notice any rough idling, decreased power or poor fuel economy, it could be a sign that there’s an issue with one or more injectors.

- Clean the injectors: over time, injectors can become clogged from carbon deposits. Whilst an additive may help, having it professionally cleaned is often a lot more effective, and necessary for severe cases

By taking these steps, you can extend the life of your diesel injectors and keep your engine running as it should. Check out our full article Diesel Injector Maintenance: A Guide to Prolonging Engine Life.

Why choose Carwood remanufactured diesel injectors

Since modern diesel injectors significantly impact engine optimisation, it pays to choose a quality brand. And whilst the aftermarket is flooded with options, unfortunately the quality is not always the same. By choosing a remanufactured injector from an OE-approved supplier like Carwood, however, you’re guaranteed a product that performs just like the original, sometimes better, with a warranty to match. Ensuring the same standards of power output, emissions performance, fuel efficiency, and longevity, as the original part. Yet, because we use the core, they cost less and are better for the environment. Making Carwood a trusted choice for current and future generation diesel injectors.