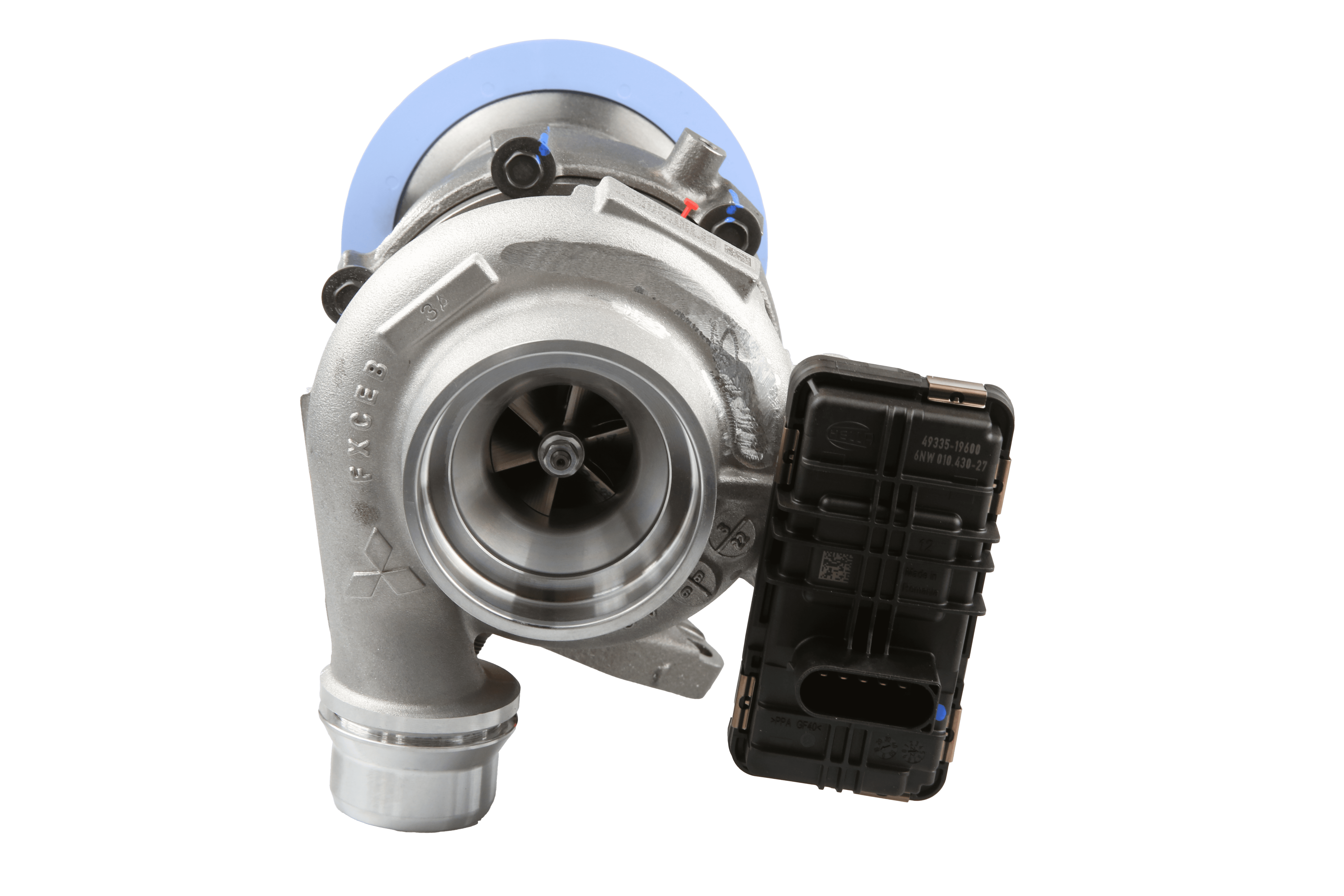

Recently, however, we’ve taken on the distribution for a growing list of OE brands too: Bosch, Denso, Delphi, Garrett and Mitsubishi, on top of our existing relationship with the likes of BorgWarner, Carbon Zapp, Eberspacher, Valeo and Hella. But why the shift in strategy? Bottom line, changing market dynamics and consumer preferences.

“The aftermarket is in a period of unprecedented change. Emerging vehicle technologies, ever stricter regulations and a proliferation of new vehicle models are transforming the industry, and quickly” explains Simon Quantrell, deputy managing director, Carwood. “At the same time there has been an accelerated shift to more cost- and eco-conscious solutions, bought on by a global pandemic, war and a cost-of-living and climate crisis. In isolation these are big changes. Together, they are massive. The aftermarket, us included, need to respond.”

Carwood has! With OE new and exchange units, OE spare parts for local repair, plus our own OE-approved reman range, our customers, can now offer theirs, a choice of competitively priced solutions for an increasingly diverse, complex and aging vehicle parc, without compromising on the quality of the product or the service on offer.

Underlining this point Quantrell adds: “More than ever, aftermarket companies need access to a broad range of high-tech parts, for an even broader range of vehicles, new and old. We also recognise that the owner of that vehicle may have different service and repair needs, based on their individual circumstances, and the type, age and value of the vehicle. Take the manager of a fleet of hybrid delivery vehicles, or a farmer mid-harvest, they’ll have very different requirements to the owner of a high-performance car with a 3.5L twin-turbo V6 engine to that of a 13-year-old vehicle, nearing the end of its lifetime. So, it’s important that you’re able to offer more than one kind of solution too. This was the driver behind our decision.”

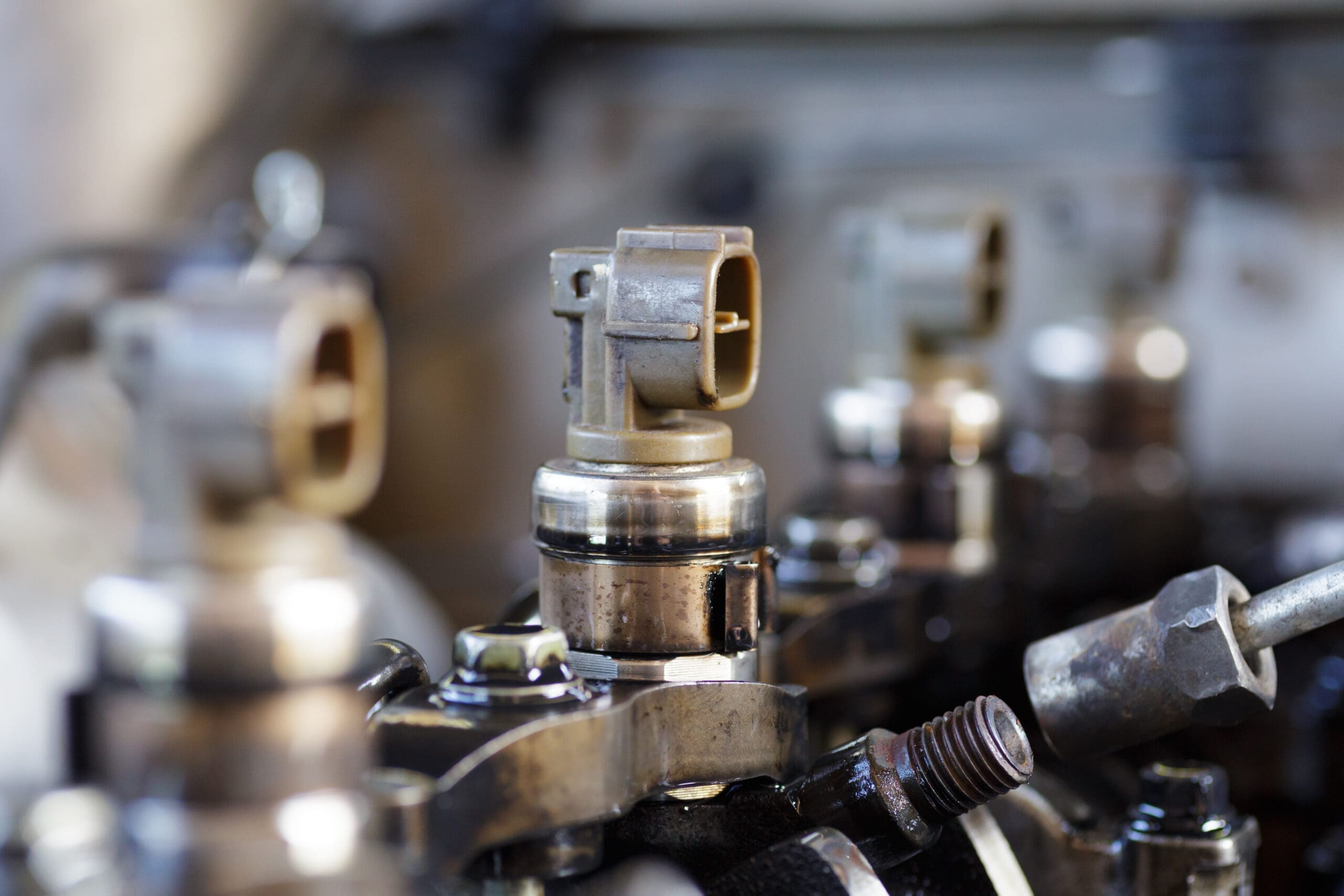

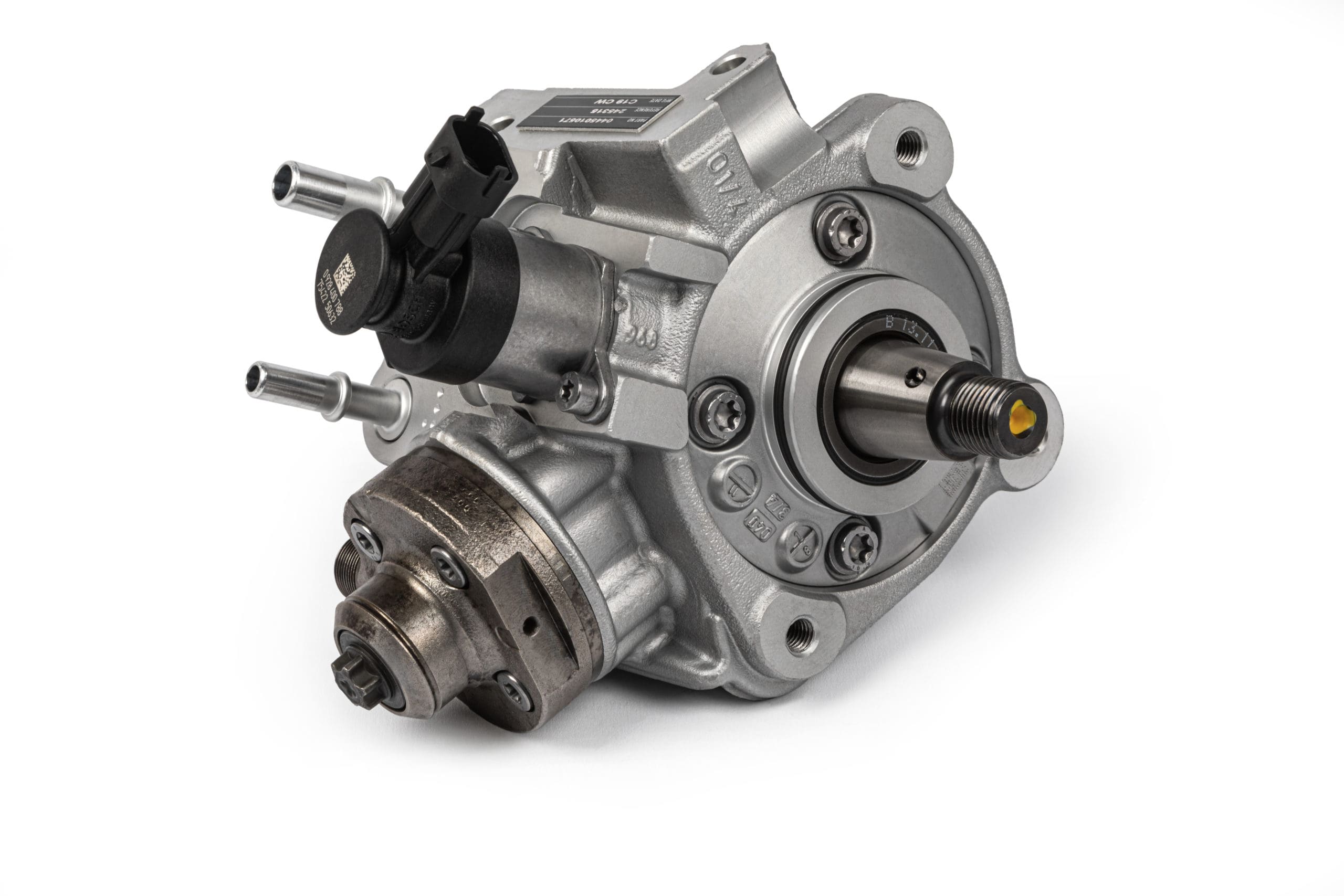

For new vehicles, for example, Carwood now offers a full range of new OE fuel pumps and injectors, turbochargers, starters, alternators, HVAC components and more. With 100% coverage from start of vehicle production (often the only solution during warranty), customers can access the parts needed for an even wider range of the latest generation vehicles, sooner.

Within two or three years of vehicle launch, a remanufactured unit will likely be a more viable solution. Whether it’s an OE exchange, or one of Carwood’s own OE-approved remanufactured units, by reusing the core, it is a much more cost and environmentally friendly option. Typically, Carwood units are at least 25% cheaper than new OE.

For a more economical repair for older vehicles, where maintenance costs are often disproportionately high compared to their value, Carwood also offers a range of OE spare parts for local repair. By replacing only components which are out of specification, this is often the most economical solution, but is subject to a leadtime.

“Whether factory new, Carwood remanufactured or repaired, every part we offer will be built to OE specification, and meet original levels of performance, longevity, fuel economy and emissions, with warranties to match. So, you can choose based on what’s important to you. That may be budget, speed of service, the logistics of returning old core (or not), or something else. The point is, there’s a choice.”

So, shifting consumer behaviours and changing market dynamics, should not be viewed as a challenge. But an opportunity to adapt and find new ways of meeting ever-evolving market and consumer needs – just like Carwood has. It does not mean changing your whole strategy – reman will always be the core of Carwood’s business – just flexing it to suit. Those that do, will be the ones that stand to gain from the current scenario. And beyond.