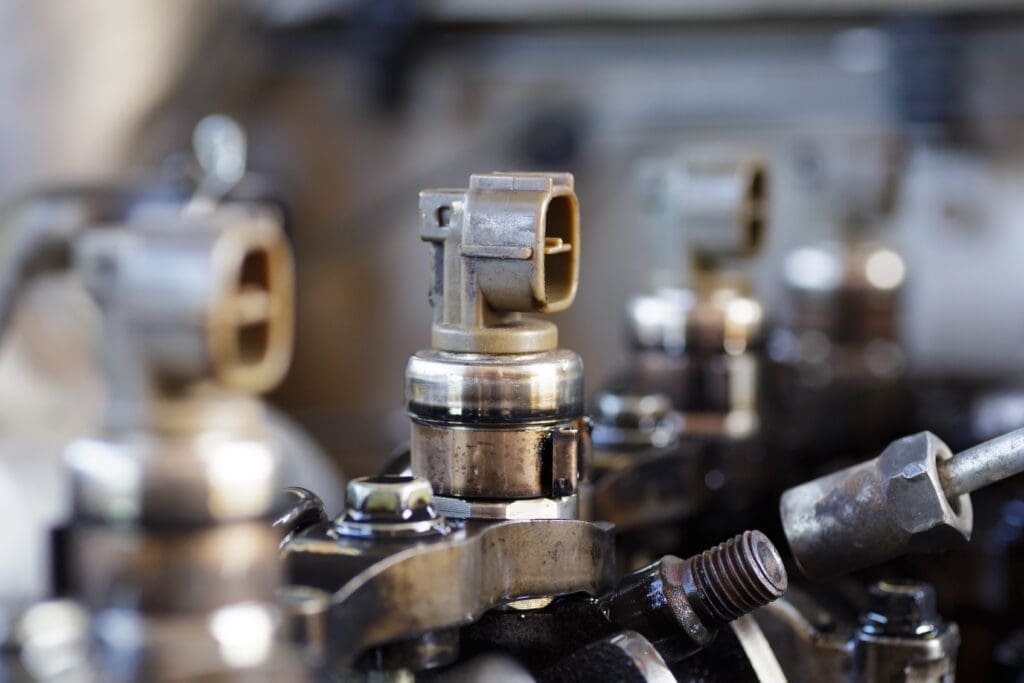

Diesel injectors: life support for the diesel engine

Modern diesel engines are designed to last anywhere between 300,000 to 500,000 miles. For most, that means the lifetime of the vehicle. Whilst factors such as usage, operating conditions, fuel quality and maintenance all have a role to play, so does the diesel injector. Responsible for delivering the right amount of diesel fuel into the combustion chamber, at the right time and pressure, for an optimal burn, it can impact the engine’s fuel and emissions performance, as well as its health and longevity.

Common diesel injector issues and their impact on engine life

So it stands to reason, that if the injector is not performing as it should, due to either a fault or a poor quality injector, the engine may not last as long. Common issues that could compromise the engine’s longevity include:

- Water contamination: whilst some water in fuel is inevitable, too much can cause significant issues. It can corrode metal surfaces, block filters and erode fuel injector surfaces, disrupting the injector’s spray pattern, and leading to reduced engine, fuel and emissions performance. Worse still, it can reduce the fuel’s lubricating properties, shortening the life of key components due to wear.

- Particle contamination: hard particulate matter or dirt can have an equally devastating effect on the fuel system, and potentially the engine. These particles can pass through the filter and erode key components such as the control valve and nozzle assembly, ultimately leading to poor engine performance, reduced fuel efficiency, component wear, and even engine damage.

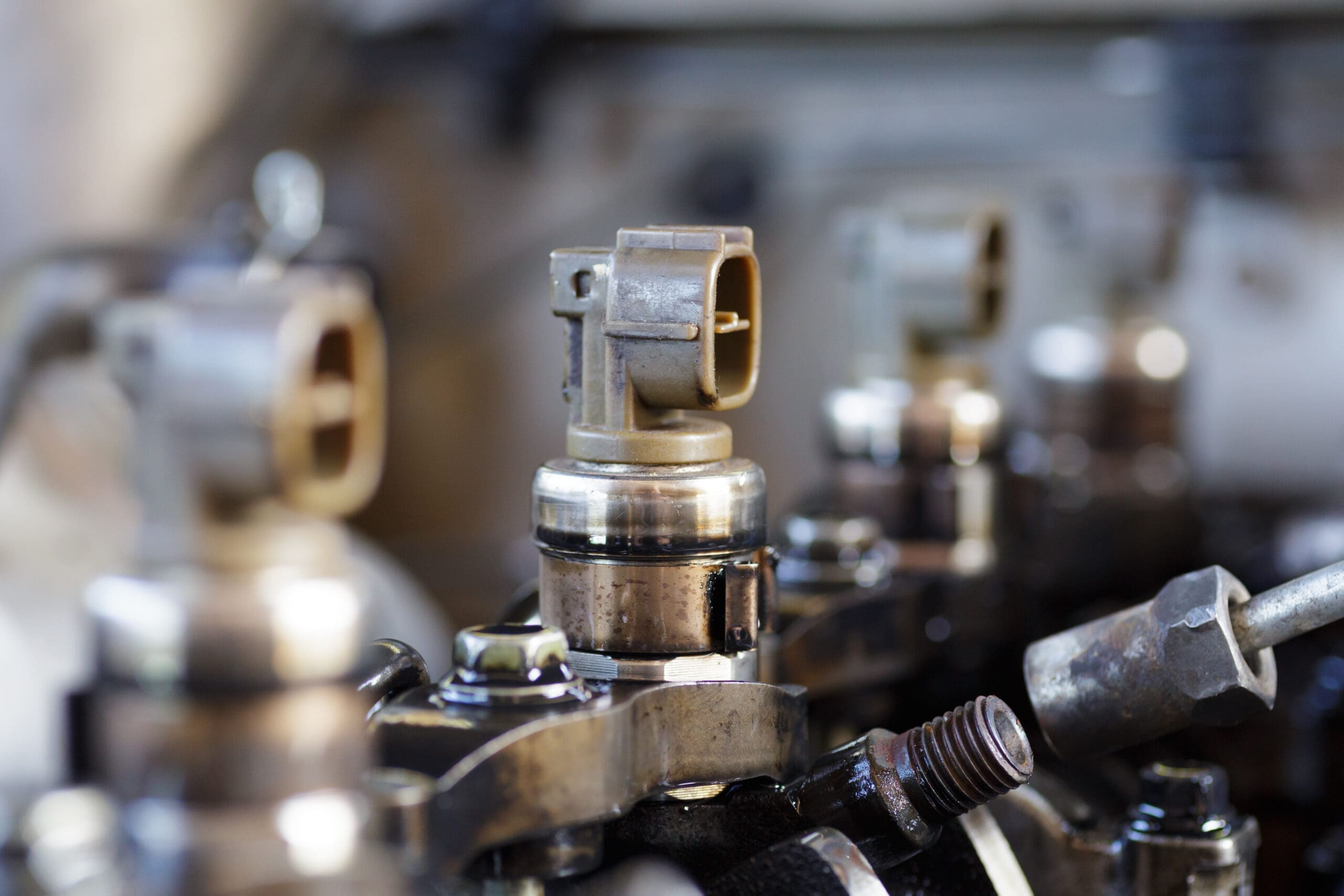

- Carbon build up: over time carbon deposits can bake onto the injector, causing it to block and/or wear prematurely, and impacting the diesel injector’s ability to correctly meter the fuel. This can cause engine knocking or misfires, which overtime, can damage pistons, valves, and even the entire combustion system.

- Solenoid failure: a short circuit from a faulty ECU, damaged wiring loom or water ingress can damage the solenoid. Since the solenoid controls the timing and quantity of fuel injected into the cylinder, this can cause excessive knocking, misfires or rough running as above.

- Broken or leaking diesel injector: on rare occasions the nozzle and/or capnut can crack or break, causing the diesel injector to leak, creating a rich air-fuel mixture. As well as impacting fuel economy and emissions, it can cause the engine to run inefficiently, putting additional strain on the pistons, rings, and cylinder walls. If left unchecked this can eventually lead to complete engine failure.

Find out more on the common causes of common rail injector failure.

Best practices for diesel injector maintenance

Regular maintenance is therefore critical in ensuring both the diesel injector, and the engine, perform and last as long as they should. It’s always a good idea to:

- Use quality diesel fuel: fill up at a reputable station to prevent the risk of harmful contaminants entering the fuel and clogging the diesel injectors. And every 1,000 miles or so, run a tankful of a premium diesel through the engine to help clean soot and other deposits.

- Use a fuel additive: similarly, you might want to consider adding a diesel additive to your tank to both improve the lubrication of key system components and help prevent the build up of deposits.

- Replace the fuel filter: fit new OE-quality fuel filters at the recommended service intervals, to protect the injector against dirt and debris.

- Check your engine: keep an eye out for decreased power, fuel economy or rough idling as this could indicate a fault with one or more injectors.

- Clean the injectors: have the injectors professionally cleaned to remove excess carbon build up which may clog the injectors.

- Avoid frequent short trips: try to avoid short trips as this can prevent the engine from reaching the required temperature for optimal combustion. It can also block the diesel particulate filter, or DPF, hampering the injectors’ ability to accurately regulate fuel pressure. If this happens, consider using a professional DPF cleaning service.

Diagnostic tools and techniques for injector health assessment

The timely replacement of worn or faulty parts is equally vital. Whilst a quick visual inspection of the diesel injectors can help identify potential problems such as carbon buildup up and leaks, being able to pinpoint which ones are at fault, and need replacing, requires specialist diagnostic tools and know-how. Trained technicians, with the right equipment, should follow this best-practice diagnostics process:

- Use an onboard diagnostic tool: plug the OBD scanner into the vehicle to read any fault codes stored in the vehicle’s engine control unit.

- Check the injector’s back leak: if the scan tool brings up a fuel injection related fault code such as injector short circuit, injector learn error, low rail pressure or lean or rich fuel mixture, fit an injector back leak kit to check the injector’s back leak flow on vehicle and confirm which diesel injector, or diesel injectors, are at fault.

- Check rail pressure: it’s also advisable to test the pressure of the common rail pump. Use an onboard diagnostic tool or sealed rail diagnostic test kit during engine cranking. If the pressure differs from the vehicle manufacturer’s specification then the common rail pump could be at fault too.

- Test the injectors electrical functionality: on DC wound coil injectors from Delphi, Denso and some Bosch, use an ohmmeter to measure the resistance across the injector’s terminals. If it is outside of the specified range this could indicate an electrical issue within the diesel injector. For piezoelectric on Continental and some Bosch, specialist tooling will be required to electrically diagnose the solenoid.

- Check the coil: a ground to earth check can also be performed to check for coil breakdown. This will require more comprehensive diagnostic tools.

Cost-effectiveness of regular maintenance vs. premature engine failure

Because prevention is always better than cure, it pays to keep both your fuel injection system and engine in peak condition. Not only will it ensure your engine is running as it should, for the entirety of the vehicle’s lifespan, but it will help save on ongoing fuel bills. It will also allow you to spot and fix any small issues, before they become much bigger, and more expensive to repair in the future.

So whilst regular maintenance and servicing comes at a cost, it is far more economical than having to replace one or more injectors, or worse still a complete engine, costing upwards of hundreds, sometimes, thousands of pounds.

How Carwood helps! Benefits of OE-approved remanufactured injectors for engine longevity

Longevity is a common theme at Carwood. After all, our role as an OE-approved remanufacturer is to keep product circulating in the economy for longer. And we aim to help keep your engine running just as long too.

By reusing core, often for multiple lifecycles, we can restore a used injector back to the manufacturer’s original specification, sometimes even better. Every part we remanufacture goes through the exact same stringent inspection, cleaning, rebuild, and test procedures as the OE, with all wearable or out-of-spec components replaced with OE. This ensures that all Carwood remanufactured diesel injectors meet the same standards of engine performance, fuel economy, emissions and durability as the OE.

We also allocate a new calibration or trim code to reflect the remanufactured injector’s new characteristics, such as flow rates, response times and performance at different pressures. This code must be reprogrammed into the ECU before it’s installed in the vehicle, to ensure that the timing and quantity of fuel are realigned for optimum engine, fuel and emissions performance. All which help prolong the engine’s life. Some remanufacturers ignore this critical step, meaning that the vehicle has to guess how to perform and will invariably be operating outside of its validated parameters, impacting the engine’s lifespan. Learn more about the importance of common rail injector coding.

Environmental benefits of well-maintained injectors

Of course a good quality, and well-maintained diesel injector, will also improve the engine’s emissions performance. With injection pressures up to 3,000 bar, millimetre-precision fuel delivery and multiple injection events per combustion cycle, modern diesel injectors deliver an optimal air-fuel mixture for a much cleaner, more efficient burn. And if the engine is working more effectively, it will use less fuel, which is good for both the environment, and your wallet. Find out more on how diesel injectors help to reduce emissions.

Better still, a remanufactured injector from an OE-approved company like Carwood, will have wider-reaching environmental benefits. By retaining the materials and value added – labour, energy, and manufacturing processes – that were embodied in the original part when it was made, remanufacturing can save up to 70% of the resources versus new, use around 85% less energy, reduce CO2 emissions and keep waste out of landfill, whilst also costing you less.

So not only can Carwood remanufactured injectors help keep the planet going for longer, by looking after them with regular maintenance and servicing, you can help keep your engine running longer too. Explore our full range of OE-approved diesel pumps and diesel injectors here.